POLYTRON

ULTRA PERFORMANCE

The Augmented Lubricant

Products

EP 2 – Lithium Complex Grease

Long Lasting, Wide Temperature Range, Effective In Severe Conditions, Significantly Reduces Wear.

How Does it works

10 WAYS POLYTRON IS CUTTING EQUIPMENT MAINTENANCE COSTS AND IMPROVING PERFORMANCE

Polytron products are different from any other lubricant or additive, using proprietary metallurgical technology to smooth and harden mating surfaces at microscopic levels to reduce friction and wear by up to 95%. From industrial machinery to fleet cars, adding Polytron to motor oil or lubricant dramatically improves performance and extends equipment life while slashing fuel, oil and maintenance costs.

Polytron’s field-tested technology eliminates the microscopic irregularities which create friction between moving surfaces. By hardening and smoothing mating surfaces, Polytron practically eliminates friction and wear, extending engine life.

Polytron’s field-tested technology eliminates the microscopic irregularities which create friction between moving surfaces. By hardening and smoothing mating surfaces, Polytron practically eliminates friction and wear, extending engine life.

Polytron’s field-tested technology eliminates the microscopic irregularities which create friction between moving surfaces. By hardening and smoothing mating surfaces, Polytron practically eliminates friction and wear, extending engine life.

Polytron’s field-tested technology eliminates the microscopic irregularities which create friction between moving surfaces. By hardening and smoothing mating surfaces, Polytron practically eliminates friction and wear, extending engine life.

Polytron’s field-tested technology eliminates the microscopic irregularities which create friction between moving surfaces. By hardening and smoothing mating surfaces, Polytron practically eliminates friction and wear, extending engine life.

Polytron’s field-tested technology eliminates the microscopic irregularities which create friction between moving surfaces. By hardening and smoothing mating surfaces, Polytron practically eliminates friction and wear, extending engine life.

Polytron’s field-tested technology eliminates the microscopic irregularities which create friction between moving surfaces. By hardening and smoothing mating surfaces, Polytron practically eliminates friction and wear, extending engine life.

Polytron’s field-tested technology eliminates the microscopic irregularities which create friction between moving surfaces. By hardening and smoothing mating surfaces, Polytron practically eliminates friction and wear, extending engine life.

Polytron’s field-tested technology eliminates the microscopic irregularities which create friction between moving surfaces. By hardening and smoothing mating surfaces, Polytron practically eliminates friction and wear, extending engine life.

Polytron’s field-tested technology eliminates the microscopic irregularities which create friction between moving surfaces. By hardening and smoothing mating surfaces, Polytron practically eliminates friction and wear, extending engine life.

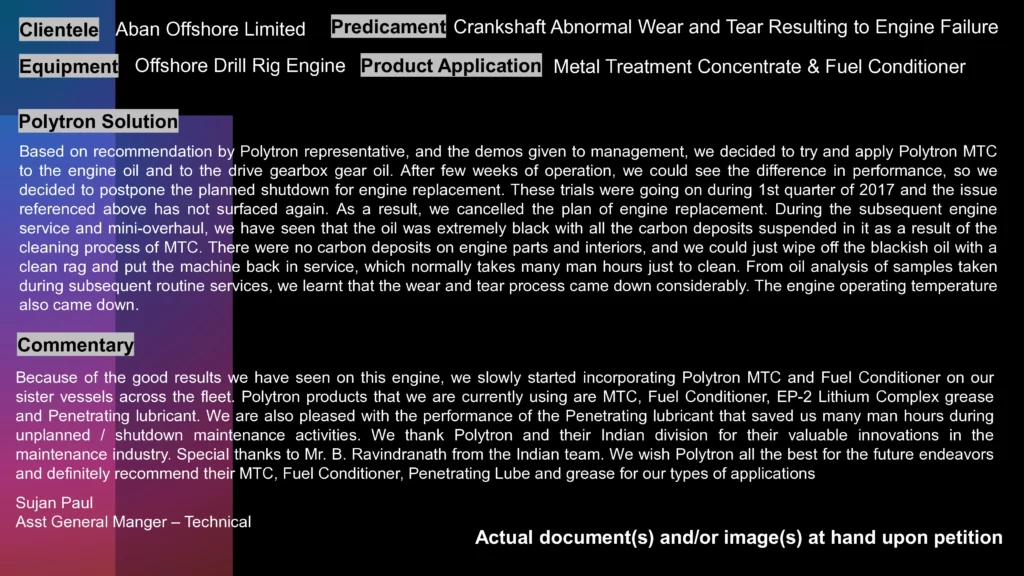

Aban Offshore Limited

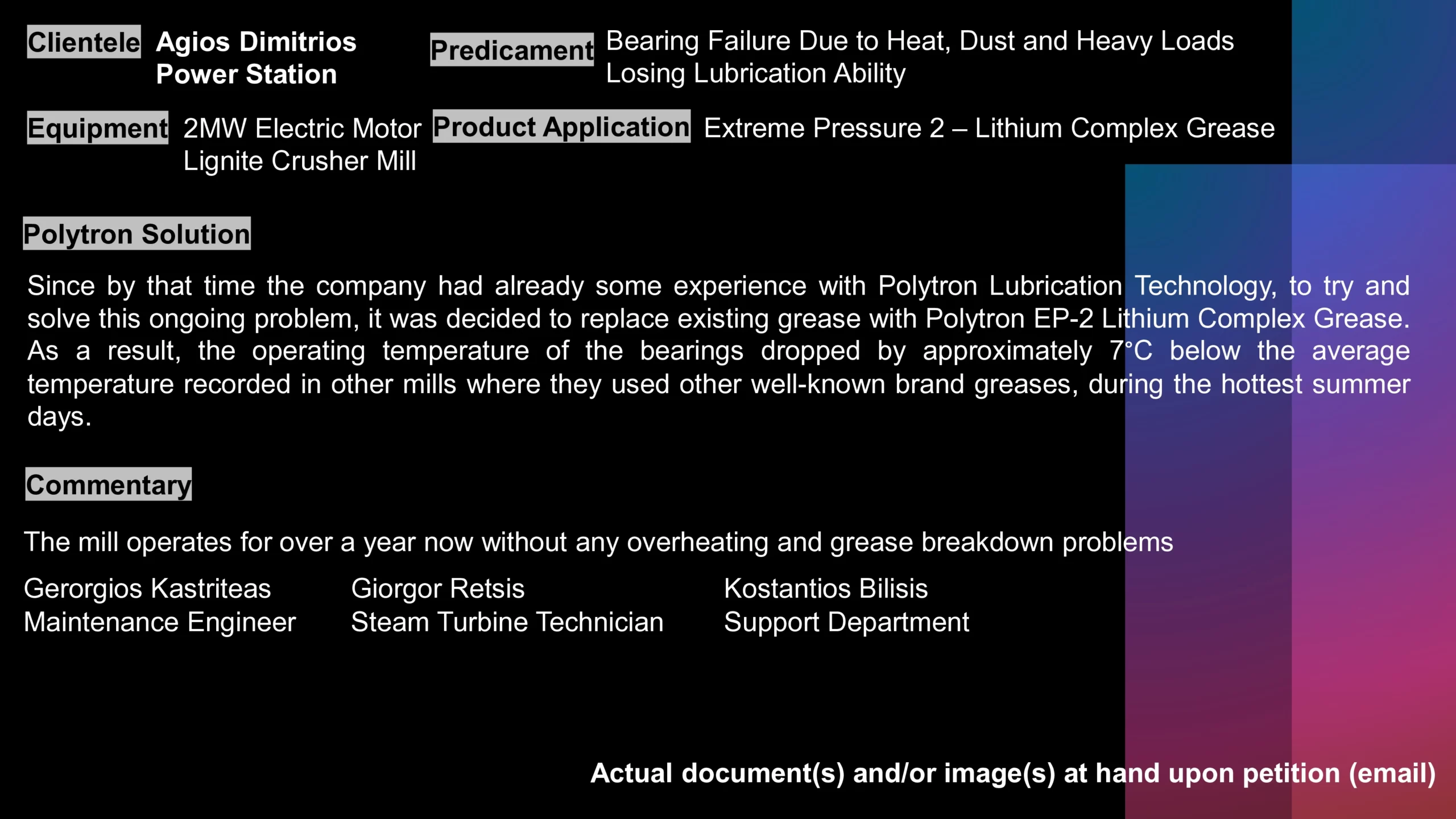

Agios Dimitrios

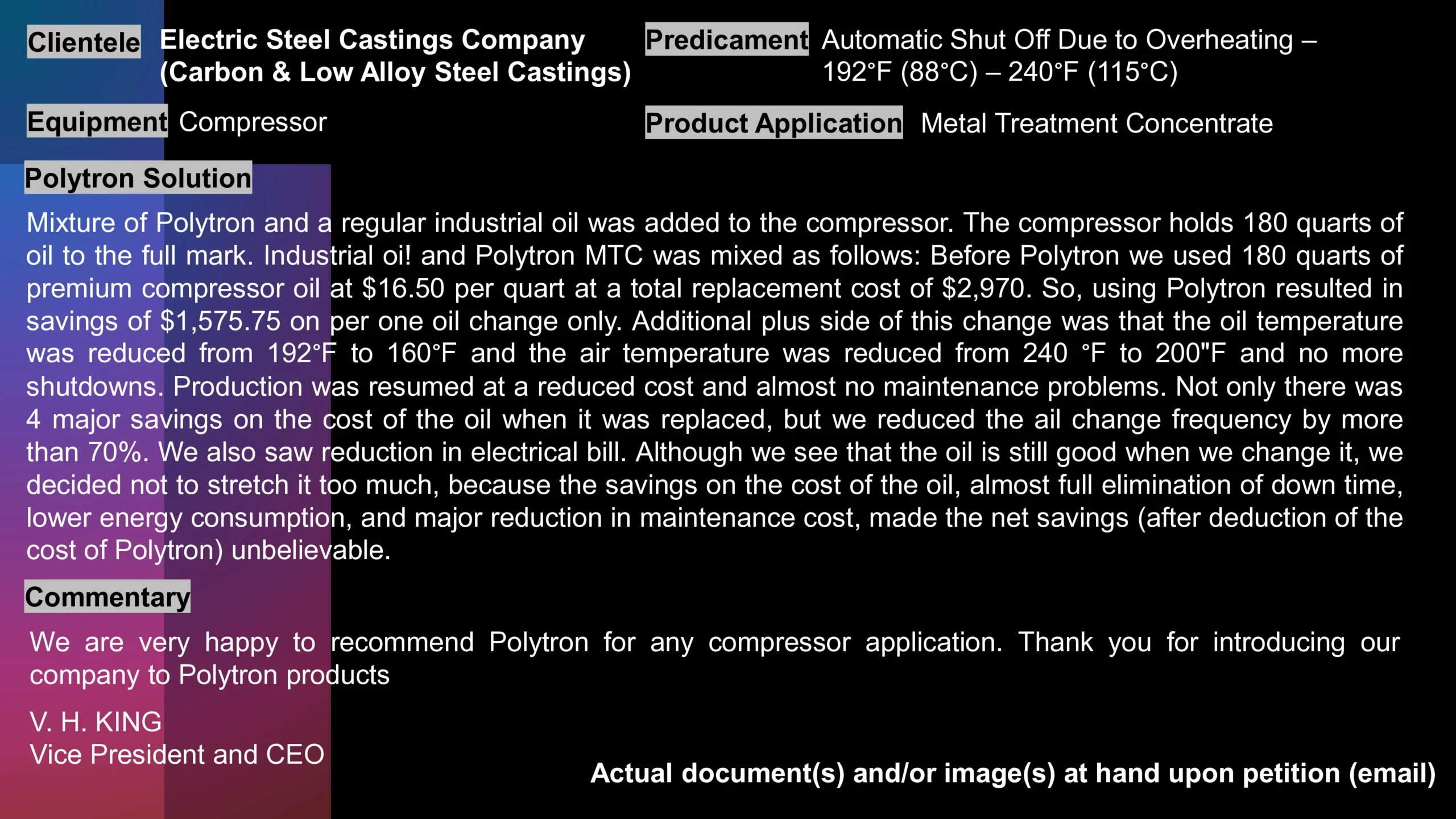

Electric Steel Castings Company (Carbon & Low Alloy Steel Castings)

Fritz Egger GmbH & Co.

GM Diesel

Hong Leong Asia Ltd.

Kolubara Lazarevak

Marble Sand Quarry Nichlos Brothers S.A.

MIDAS IT Services India Pvt. Ltd.

P.T Indo Mega Maritim

Pacific Radiance Predicament Crest Subsea International

Pepsico

Sakthi Murugan Agro Foods Ltd.

SAMWOH Group of Companies

SBI-E&M - Engineering & Manpower Services Ltd.

TPP Nikola Tesla Elektroprivreda Srbije

Tridonicatco Sdn. Bhd

Uncle Sasha, LLC

White Pass & Yukon Route

Wietersdorfer and Peggauer Zementwerke GmbH

UNDER CONSTRUCTION

FAQ

Frequently Asked Questions

For vehicles with a standard five-quart crankcase capacity, add 1 bottle .473ml of Polytron MTC to the crankcase. Then fill to the recommended capacity with the motor oil normally used. With larger volume systems, use Polytron MTC by 10% in volume.

Polytron’s field-tested technology eliminates the microscopic irregularities which create friction between moving surfaces. By hardening and smoothing mating surfaces, Polytron practically eliminates friction and wear, extending engine life.

Polytron’s field-tested technology eliminates the microscopic irregularities which create friction between moving surfaces. By hardening and smoothing mating surfaces, Polytron practically eliminates friction and wear, extending engine life.

Polytron’s field-tested technology eliminates the microscopic irregularities which create friction between moving surfaces. By hardening and smoothing mating surfaces, Polytron practically eliminates friction and wear, extending engine life.

Polytron’s field-tested technology eliminates the microscopic irregularities which create friction between moving surfaces. By hardening and smoothing mating surfaces, Polytron practically eliminates friction and wear, extending engine life.

Polytron’s field-tested technology eliminates the microscopic irregularities which create friction between moving surfaces. By hardening and smoothing mating surfaces, Polytron practically eliminates friction and wear, extending engine life.

Polytron’s field-tested technology eliminates the microscopic irregularities which create friction between moving surfaces. By hardening and smoothing mating surfaces, Polytron practically eliminates friction and wear, extending engine life.

Polytron’s field-tested technology eliminates the microscopic irregularities which create friction between moving surfaces. By hardening and smoothing mating surfaces, Polytron practically eliminates friction and wear, extending engine life.

Polytron’s field-tested technology eliminates the microscopic irregularities which create friction between moving surfaces. By hardening and smoothing mating surfaces, Polytron practically eliminates friction and wear, extending engine life.